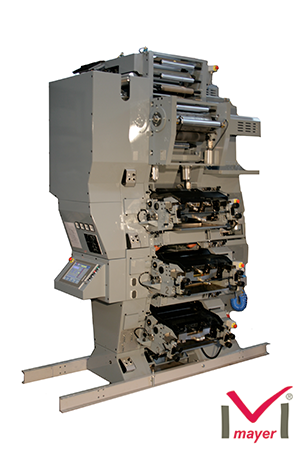

Efficient flexo stack press machines:

Compact with color units arranged vertically.

The stack flexo printing technology features compact print stations with easy access to chamber doctor blade systems arranged vertically one above the other. Between the print units, driers may be installed so that subsequent colors can be applied to the substrate without merging into those previously printed.

These driers may utilize hot air, infra red or ultra-violet light, depending on the application. For efficient drying VelociDryer™ by TRESU is recommended.

Flexo stack printing solutions are configured to customer specifications:

• Up to 3 colors on each stack without platform

• Up to 6 colors on each stack with platform

• Print width from 400 mm to 1700 mm

• Speed up to 600 m/min

• Register control with minimum waste

• 100 % controlled web-tension

• State of the art drying process with VelociDryer™ by TRESU drying technology

Stack presses are less suitable for thin or extensible substrates. For those kind of applications the multi-station inline flexo print design is better suited.

FLEXO STACK PRINTING PRESSES - INLINE RETROFIT UNIT: | |||||||||||

| This 4-color stack printing press is retrofitted inline in a converting line for bags. Dryers are placed between the printing units and an additional drying unit is placed after the print units. The stack press features semi servo driven units enabling 2 different web paths - operating either 4 + 0 or 2 + 2 - just by adding this additional retrofit unit. TRESU flexo retrofit units can be supplied with: | ||||||||||

Our flexo stack printing concept can be integrated in different ways - feel free to reach out and let us discuss how to find the best stack press for your application.