Flexographic printing presses

Based on the heritage from 40 years of proven performance and with built-in know-how from projects with leading brands all over the world, TRESU offers a range of proven printing presses and coating machines customized for the purpose – either integrated inline or as stand-alone solutions.

In fact, our flexo printing machines handle multiple kinds of media and substrates including:

- folding carton

- liquid or flexible packaging

- paper

- pre- and post-printing for corrugated

- nonwoven

- films, foils or plastic

Why flexo technology?

Well, HD-printing, high-quality standards, high production speeds, fast job changes as well as cost-effectiveness have made flexo the most attractive printing technology today and a viable alternative to gravure and offset.

Flexographic press types.

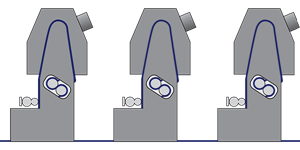

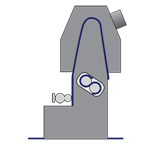

Depending on how print or color stations are placed in the overall setup of the printing machine, TRESU offers three main types of printing presses:

Inline flexo press technology - either as multistation or as a single unit - and if space is limited either flexo stack or flexo CI technology.

| ||

| Click for info: Innovator: Inline multi-station flexo press | ||

|  |  |

| Click for info: Inline flexo retrofit unit | Click for info: Flexo Stack | Click for info: Flexo CI |

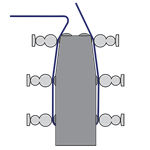

Innovator: Inline multi-station flexo press - horizontal layout in a line.

The inline multi station press is equipped with individual print stations placed sequentially one after the other at ground level along a web path with multi-process printing and converting operations inline for a single pass production setup.

The applications of inline flexo printing include the printing of folding carton, pre-printing for corrugated, décor, liquid packaging, flexible packaging, bags, sacks, shrink sleeves, films, foils, plastic, labels, liquid packaging, nonwoven, paper, lottery tickets, tissue and coating or special applications.

Flexo stack press with color units stacked one above the other.

This printing press technology features compact print stations with easy access to chamber doctor blade systems arranged vertically one above the other.

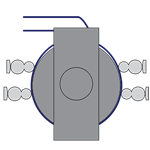

Flexo CI press - when space is limited and quality requirements high.

A planetary setup based on a central impression and the color units with chamber doctor blade systems placed around the central impression cylinder.

This is ideal for web-to-web printing with precise print register, tight tolerances, a high number of impressions per output and thin extensible substrates.

Examples are narrow-web printing units for nonwoven like sanitary napkins or tissue, as well as dishwasher pouches.

Benefits from an efficient supply chain with flexo technology:

- Widest range of water-based inks - easy to work with and fast to dry

- HD flexo printing plates are relatively straightforward to manufacture

- Printing on a wide range of substrates is possible

- High level of automation and connectivity is possible

Applying genuine TRESU technologies like Pressure Control Technology, VelociDryer™ and automated ink supply, we create efficient solutions, that will extend your performance and last in the long run.

Contacts

HENRIK KRISTENSEN

CSO

SALES

email: HKr@tresu.com

mobile: +45 2941 8386