S-Mount: Automatic plate mounting, registration and impression.

- Automated plate mounting is significantly faster than manual plate mounting

- Consistent in precision, no more downtime caused by improper mounting of printing plates

- Easy transfer of job recipe data and greater accuracy

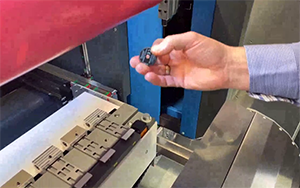

Automated plate mounting |

RFID transfer of data from plate to print unit |

S-Mount: Intelligent plate mounting

Increased mounting efficiency

The automated process is more efficient than manual mounting. Plate mounting takes approx. 40 seconds.

Higher press efficiency

The automated process is consistent in precision. Therefore, there is less downtime caused by improper mounting of the printing plate.

Automatic makeready

The IRIS - Intelligent Register and Impression Setting - system will preset optimal printing settings which speeds up the makeready time on the press and reduces the waste often created during setup.

Efficient & versatile

When mounting plates automatically, the operator can prepare additional plates, tape, sleeves or create a recipe for a new job.

The unique, manual mounting of tape is possible directly on the fully automatic plate mounter. S-Mount can also mount plates for machines with different core diameters and sleeve lengths.

Intelligent automation

The S-Mount connection to the press, via RFID chips integrated in the printing plate sleeves, ensures the easy transfer of job recipe data, offering Intelligent Functions such as Auto Impression settings and other intelligent functions unique in the market.

Retrofit solutions

To get the full benefit of the S-Mount functionalities, a minor upgrade of your Innovator is needed. In retrofit solutions, both software and user interface on the innovator needs to be updated with scanner and software.

S-Mount technology highlights:

Before automated alignment of the printing plate |

Automated IRIS scanning of print plate circumference |

After automated alignment of the printing plate. | ||||

Click HERE to access datasheet.

Contact information:

sales@tresu.com