Increase productivity: | ||||||

The best way to explain TRESU’s VelociDryer™ technology works, is to think of a washing line. Optimum drying conditions include high velocity air as the key factor: On a hot summer day with low humidity and no wind, it will take a while for the laundry to dry, but on a cold day with a lot of wind, the laundry will dry fast. If there is only a light breeze, the time it takes to dry the same amount of laundry will increase. Wind – and the air velocity - is the key factor in any drying proces.

|  Washing line - high velocity wind is key to drying. |

VelociDryer™ by TRESU: Proven drying technology.

Heat and speed are critical components when drying inks and coating - and the right drying can be the difference between outstanding results, good enough results – or simply waste. TRESU's hot-air drying technology optimizes process efficiency by applying a relatively high air velocity with a short distance between the nozzles and the substrate in combination with the right temperature.

In a multi-station printing press, air drying and/or UV curing units are included between each printing unit, with ample ventilation to ensure all moisture is extracted from the material before the next conversion.

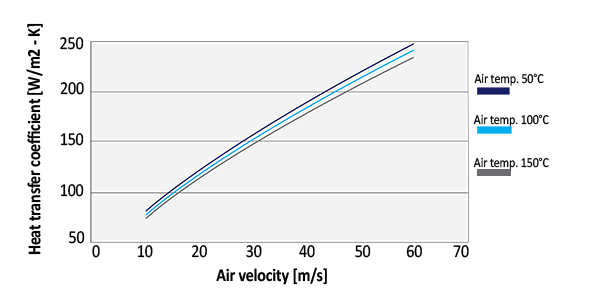

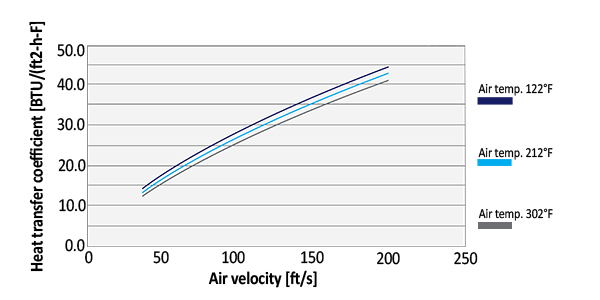

Heat Transfer and Air Velocity - Celsius

| Heat Transfer and Air Velocity - Fahrenheit

|

Increase productivity: Get more from existing installations.

Using your existing press, ink, coatings, substrates and workflow software and workforce, by adding high-velocity drying technology your press line can run faster and boost your output and productivity – while maintaining print quality, reducing the environmental footprint and achieving energy efficiencies.

Equally, with enhanced speed and reliability, more jobs per day are possible, creating opportunities for new work from new, larger, customers, more work from existing ones.

To facilitate job changes and recalling settings for previous jobs, a semi-automatic recipe control system stores drying parameters for fast and easy job changes.

Furthermore, ATEX certification options including EN 1539:2015 standards and safety surveillance for converters using solvent ink or working in hazardous environments are available.

Receive our technical paper on drying technology.

Click here to SIGN UP FOR THE TECHNICAL PAPER and read about the technology behind Veloci-Dryer™ by TRESU - in short, read how to get more from what you already have.

Sustainable retrofitting of high-performance drying technology opens up new opportunities.

Our drying units recycle up to 80% of the air and customers are able to control the web temperature from the drying hoods by means of monitoring sensors and chill rollers at each station - even in an inline flexo printing setup with multiple printing units.

TRESU drying systems may be specified with either gas or electricity as heating source for high velocity drying to meet the environmental requirements of converters and their customers while ensuring drying efficiency. Apart from having the choice when installing new equipment, heat sources can also be changed when retrofitting.

Inline flexo is especially beneficial for fast water-based printing, where a longer web path between printing stations is possible. TRESU drying units offer up to 12 meters (40 ft web length) and widths up to 3.5 meters (150”). Inline flexo offers the flexibility for converting thinner, lighter and recycled packaging substrates at high speed and delivering outstanding color results with water-based inks.

At TRESU, we have converted gravure and direct-reverse gravure jobs to flexo, thanks in part to the performance of the drying and curing systems. The right drying capability is also a key component of sustainable coating and printing solutions.

In fact, retrofitting an existing line, can allow producers of folding carton to apply thick water-based coatings at speeds up to 2,600 ft./min using an inline coating unit with high-speed hot-air drying.

Instead of buying multiple kinds of boards, regular standard board can be sourced and specific water-based coatings added in an inline production.

This reduces the need for keeping different grades of board in stock and makes for more efficient sourcing of boards. With an in-line setup the entire production process is controlled in a single-pass in-house operation.

Receive our technical paper on drying technology.

Click here to SIGN UP FOR THE TECHNICAL PAPER and read about the technology behind Veloci-Dryer™ by TRESU - in short, read how to get more from what you already have.